Privacy warning

With the click on the play button an external video from www.youtube.com is loaded and started. Your data is possible transferred and stored to third party. Do not start the video if you disagree. Find more about the youtube privacy statement under the following link: https://policies.google.com/privacyThe production of aircraft shells in small series is characterized by manual labor and high flexibility. For large series, automation with complex robotic cells is worthwhile, although flexibility in production is severely restricted.

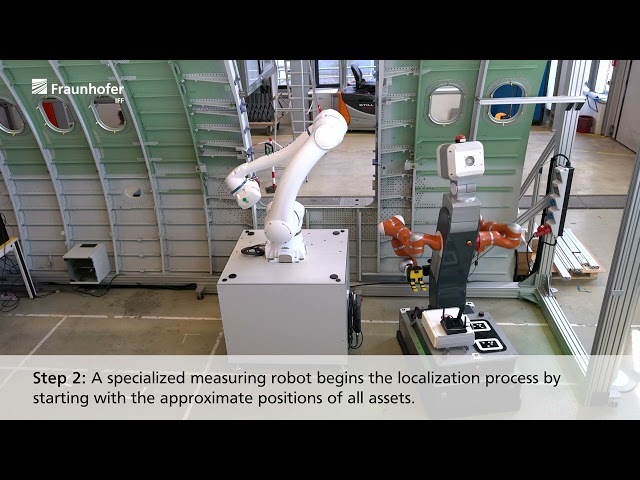

The project aims to pursue an intermediary approach. Today, the production of small batches can be significantly supported by location-flexible robot systems. They process components with laser methods and assemble essential areas of the body shells with rivets. Mobile measuring robots ensure quality, i.e. they automatically measure location-flexible machining robots and check the results of machining. This is achieved by autonomy of the robots and robot-robot cooperation. The actions of the robots are generated automatically. There is no need for human operators. In addition, different processes can be implemented flexibly.

The SWAP-IT architecture ensures scalability and optimized utilization of operating resources.

Fraunhofer Group for Production

Fraunhofer Group for Production